Home > Products > aluminum radiator tank riveting machine > aluminum radiator tank riveting machine

aluminum radiator tank riveting machine

- Product Item : 13

- Category: aluminum radiator tank riveting machine

- pneumatic system

- servo system

- Product description:This machine is show you how to assemble aluminum radiator tank and head plate together use rivet. working process: 1.put the head plate on the machine . 2.put the radiator tank on the machine.

1. PRODUCTS

To rivet total 6 rivets, each side is with 3 rivets, both side reivting symmetrically.

Customer components must be consistent in dimensions.

2. MACHINE DETAILS

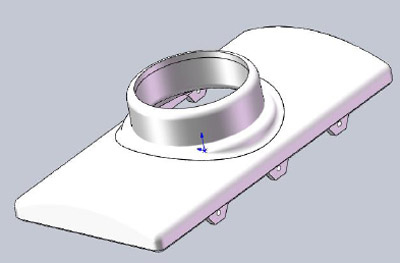

3. TOOL FOR TANK SET ON THE MACHINE

4. OPERATION PROCESS

Manual input tank and header plate ---- Press Start Button ---- Both Side riveting Same time symmetrically ---- Movement per Y Axis ---- Finish Riveting ----- Manual Remove Riveted Products

5. MACHINE DIMENSIONS

6. MACHINE FEATHERS

1).Machine auto rivets the components through vibration disk and blowing pipe to auto feed rivets, workers only need to be responsible for loading/unloading products;

2) Riveting speed is fast. By servo motor needed only around2.5-2.8s /rivet, by stepping motor is about 2.8-3.2s /rivet. Stable performance and can continuous high strength work;

3) Good compatibility, fast wire change speed, only need to call the corresponding program and place corresponding fixture;

4) Machine is with protective cover and also safety gate to protect the operators.

7. MACHINE PARAMETERS

1) Effective Stroke: X:0, Y:250, Z:0

2) Positioning Precision: ±0.2mm

3) Driving Type: Ball Screw

4) Working Efficiency: 2.5-2.8S/Rivet (By servo motor)

2.8-3.2S/Rivet ( By stepping Motor)

5) Working Evironment: (-10℃-40℃)

6) Control System: PLC

7) Rivet feeding way: Air Blowing

8) Pneumatic Components: Airtac

9) Guide rail: HIWIN

10) Power Supply: Taiwan Meanwill

11) Voltage: 220-240V AC

12) Air pressure: 0.5-0.6Mpa

13) Tank to Header joint will be less than 0.08 mm after riveting

14) Riveting time is around 20S without loading time.

15) Clamping fixture are using plastic material and will not damage the pipe opening on the tank

8. PACKING :BY SEAWORTHY PACKING

9. SHIPMENT:WITHIN 70 DAYS AFTER RECEIPT OF DOWN PAYMENT

10.PAYMENT TERMS:50% DOWN PAYMENT BY T/T

50% BALANCE PAYMENT BEFORE SHIPMENT BY t/t

Products Category

- Foam Pump assembly machine

- Fan impeller blower wheel assembly machine

- Spray cap assembly machine

- Toys gearbox automatic assembly machine

- Curtain pulley automatic assembly machine

- perfume cap assembly machine

- Diptube assembly machine

- tube cutting machine

- automatic riveting machine

- car door lock assembly machine

- bearing assembly machine

- aluminum radiator tank riveting machine

CONTACT US

Name: Miss liu

Mobile:+86-18123647785(Whatsapp/ Wechat)

Tel:+86-18123647785(Whatsapp/ Wechat)

Email:sales1@automatedline.com

Add:Dansan Science and Technology Park, Wuhu Tong, No.1, Pang Village, Chashan Town, Dongguan City